The unsung superheroes of an incredible cabinet installation.

In this modern age, one of the reasons cabinets have been able to be brought to us as affordably and reliably as they have is because of the magic of “economy-of-scale”– to a kitchen designer or installer, this translates to standardization and incrimentalized sizes. What does this have to do with fillers? In the case of IKEA cabinets, this means that cabinet widths are only available in increments of 3″ or 6″ between the ranges of 12″ and 36″ (specifically 12″, 15″, 18″, 21″, 24″, 30″, and 36″.) Heights in our favorite Swedish cabinet brand go in increments of 5″ (specifically 10″, 15″, 20″, 30″, 40″, 80″, & 90”.) Note: not all combinations of height, width, and depth exist.

Almost certainly, if you are installing cabinets in a given space–and this is especially true if you are installing them wall to wall, that space is very unlikely to be evenly divisible by 3″. Even if it were, it is inadvisable to slide a cabinet right up against a wall (laterally), unless it’s a corner cabinet, because your standard IKEA hinge opens greater than 90° (normally 110°.) All of this information points to the same conclusion. There should be a way to fill in that necessary and predictably present space! Good news: there is, and that’s exactly what fillers are for.

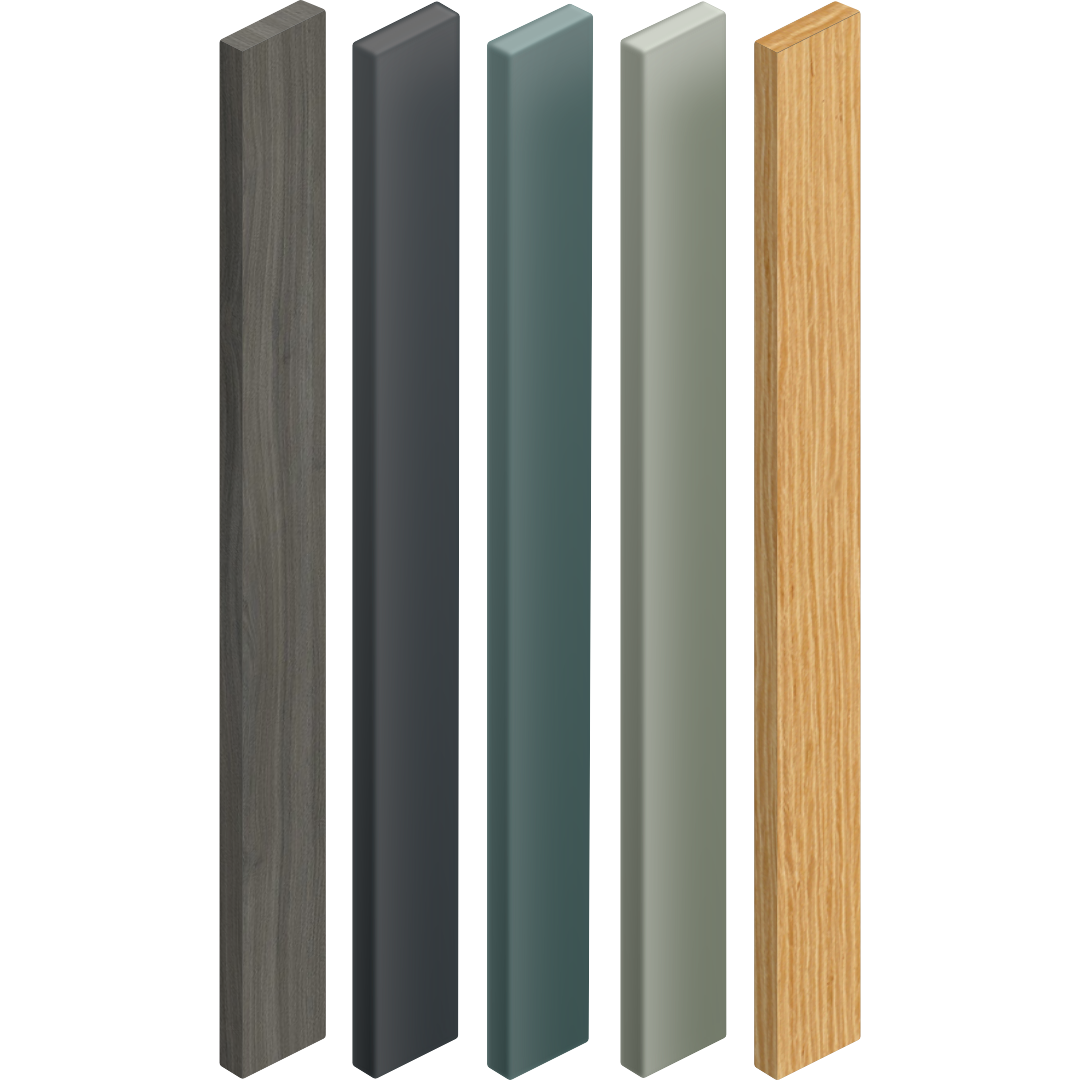

What is a filler? A filler is a narrow piece of wood or wood product that looks similar in color/material/wood species to your doors used to “fill” in a small space. This filler is able to be trimmed or scribed so that it fills in a narrow gap (usually, but not always, 3″ or less.) For that reason, our standard size filler is 3″ wide, it can be made in all of the various standard heights, and is ¾” thick. I mention standard sizing at this point just to help give the layperson a better idea what they’re likely dealing with.

Custom Fillers

Of course, we can make custom fillers. You will notice “custom filler” in the order builder. This allows you to specify exactly the width and height of a flat filler. We recognize that every house is unique, and sometimes you need something specific to finish out your installation.

Scribing a Filler

If you’ve ever watched a professional install a kitchen you may have noticed that they will often spend a lot of time fussing over the spots where the cabinetry meets the floors/walls/ceilings. This is because almost all floors, walls, and ceilings are not flat, plumb, or level. If your walls are flat, plumb, and level–congratulations! This is a rare occurrence and you should shake the hands of the people that built your home!

In order for your cabinetry to function properly, the cabinet boxes must be installed level, square, and plumb–even if the house is not. Cabinets that are not installed square or level will experience doors and drawers that will not open/shut properly or worse depending on the severity of the situation. This is where scribing comes in. Let’s take a look at an example:

Above: we are imagining that there is a row of cabinetry, installed properly (plumb, level, and square) but the wall that they will be terminating into is not plumb. This is being demonstrated by a filler held plumb and a gap is observed where the gap up top is small and the gap down below is larger. It is a good exercise to check your walls with a spirit level to verify what you are seeing!

In this example, a person should transfer the uneven (out of plumb) line onto the filler and cut the filler to the scribe line just made. So the two big questions are: exactly how do you make a scribe line and exactly how do you cut a scribe line? Answer: Any way you can (safely!)

There are many tools out there for creating a scribe-line, but you need some way of holding your filler perfectly plumb and level against near the very surface you’ll be scribing to. Then you’ll use a pencil with a stand-off to trace the unique shape of said surface onto the filler. This is an over-simplification, because it’s nearly impossible to describe every unique situation. YouTube and Google are your friends!

Next: the cut. If the scribe line is straight, but not plumb, then it is simply an angled cut and a person can use a handheld circular saw or a table saw with a clamping sled mechanism attached. If the line is also not straight, you may need to use a reciprocating saw or a bandsaw. There are many other strategies which can be used in various situations. You can cut a straight line with whatever tools you feel most comfortable with which is close to the scribe line, but then finish the rest of the “cut” with an orbital sander and a heavy grit.

I recommend searching the internet or contacting a professional if you are not comfortable enough to begin such a task as this. If you are able to make a practice cut or two on some scrap material first, that may be wise. Give it a go and hold your practice cut up to the wall you’re trying to scribe to. Adjust and try again.

There are endless YouTube videos or blogs that demonstrate how to make scribe lines and scribe cuts using all sorts of different tools and methods. If the end result is close, but not perfect, you can always use paintable caulk to fill in the gap. Don’t beat yourself up if you need to get a professional or a handy person you know in your home to help. This is one of the skills that helps the professionals’ work stand out from the rest.